Type of Transformer Losses

There are two components that make up transformer losses. The first is “core” loss (also called no-load loss), which is the result of the magnetizing and demagnetizing of the core during normal operation. Core loss occurs whenever the transformer is energized; core loss does not vary with load.

The second component of loss is called copper or load loss (I2R loss), because these losses occur in the windings of the transformer. Copper loss is a function of the resistance of the winding materials and varies with the load on the transformer.

Variation of Transformer losses during operation

The Transformer losses vary during the operation due to loading, voltage changes, harmonics and operating temperature.

Variation of losses with loading level

The basic D.C. resistance copper losses are assumed to be 90% of the load losses. Eddy current losses (in conductors) are assumed to be 10% of the load losses. Basic I2R losses increase with temperature, while eddy losses decreases with increase in temperature. Thus, 90% of the load losses vary directly with rise in temperature and 10% of the load losses vary inversely with temperature. Calculations are usually done for an assumed temperature rise, and the rise in temperature is dependent on the total losses to be dissipated.

The basic D.C. resistance copper losses are assumed to be 90% of the load losses. Eddy current losses (in conductors) are assumed to be 10% of the load losses. Basic I2R losses increase with temperature, while eddy losses decreases with increase in temperature. Thus, 90% of the load losses vary directly with rise in temperature and 10% of the load losses vary inversely with temperature. Calculations are usually done for an assumed temperature rise, and the rise in temperature is dependent on the total losses to be dissipated.

Operating temperature = Ambient temperature + Temperature rise.

Variation in Constant losses

The iron losses measured by no load test are constant for a given applied voltage. These losses vary as the square of the voltage.

Variation in iron losses due to system voltage harmonics

The system input voltage may contain voltage harmonics due to aggregate system pollution in the grid. The current harmonics of the local harmonic load adds to this by causing additional harmonic voltage drop depending upon magnitude of a particular harmonic and the system short circuit impedance at the point of supply, and the transformer impedance for that specific harmonic frequency. The combined total harmonics affect the flux waveform and give added iron losses. The increase in constant loss is quite small, due to this voltage distortion.

Variation in Load Losses

Load Losses = ( Per Unit Loading)2 x Load Losses at Full Load x (F + Top F + Tref)

Where,

F = Temperature Coefficient = 234.5 for Copper & 227 for Aluminium

Tref = 750 C usually, or as prescribed in test certificate

About 90% of the load losses in a Transformer as measured by short circuit test are due to I2R losses in the windings. They vary with the square of the current and also with winding temperature.

Variation in load losses due to load power factor

Any reduction in current for the same kW load by improvement in power factor reduces load losses.

Variation in losses due to current harmonics

The system current harmonics increase the r.m.s current and thus increase the basic I2R losses. In addition, the major increase comes from the variation in eddy current losses in the windings (Usually 5 to 10% of the total load losses), which vary with the square of the frequency.

Optimising Transformer Operation

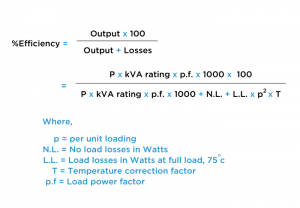

From the above explanation it is quite evident that core or no-load losses in transformers are constant irrespective of load whereas copper (I2R) losses vary with load. So to optimise transformer operation it becomes necessary to monitor the effect of varying load on the transformer.

To achieve this Real Time Monitoring System installed on a transformer plays a key role:

- It helps in monitoring the load patterns, which helps to conclude whether the transformer is under loaded, overloaded or optimally loaded. If a transformer is under load then in that case due to light loading operation of the transformer, it is considered less efficient as % energy losses will be high. Whereas overloading or loading transformers up to its rated capacity of may increase load current & I2R losses leading to reduced efficiency.

- Generally iron losses are constant with varying load but it may vary with variation in system voltage & voltage harmonics. These losses vary as the square of voltage. So it also becomes an important monitor variation in voltage & voltage harmonics.

- Power factor also plays a key role in transformer losses. If load is having a low lagging power factor, it may lead to high load current increasing I2R losses. Whereas any reduction in current for the same kW load by improvement in power factor reduces load losses (I2R losses). So it becomes important to monitor power factor for optimum operation.

- In general, selection of only one transformer of higher rating gives maximum efficiency and simpler installation. For large plants with long plant distances, two or more transformers of equal rating may be selected. Moreover for critical continuous operation plants, power may be obtained from two independent feeders at similar or different voltage levels. In all such cases, each transformer may be sufficient to run the plant. Thus normal operation may be at 50% load. Such a situation may lead to lower than 25% load at some times. For non-continuous operation of plants with holidays or seasonal industries, switching off one transformer to save part load losses is generally considered. In such cases real time monitoring plays a key role, by virtue of this proper load management & scheduling can be planned leading to optimum transformer operation.

Motwane provides a Digital Transformer monitoring solution – IoTx, it monitors and provides alerts for abnormalities through email & sms. IoTx with Motware – Our in-house cloud based analytic platform provides graphic representation of your test records for trend analysis and reporting.