- The transformer core is immersed in the oil, which acts as an insulating medium between the windings.

- Transformer oil acts as a coolant and dissipates heat produced in the windings due to iron and copper losses.

- The chemical and electric properties of this oil change if there is a degradation in transformer health. Thus, transformer oil tests give information about the severity of faults related to aging and water contamination.

- Transformer oil helps in determining any internal fault via Buchholz relay.

- The insulating oil also suppresses the arcing and reduces the corona losses.

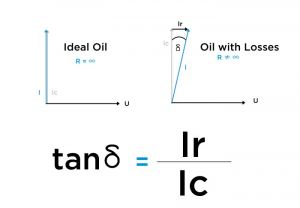

We know that if any dielectric is placed between two conductors, then the whole system works like a capacitor. Here the two windings are analogous to two conductors, and the insulating oil acts as a dielectric. Therefore, ideally, the current through the transformer core (or capacitor) should lead the voltage by 90°. This ideal condition is valid when the dielectric material is cent percent pure and is devoid of any resistive component.

However, in practice, the dielectrics aren’t perfect. It means that the capacitive current leads the voltage by an angle that is less than 90° . Factors like the aging of transformer/oil, impurities, improper filtration methods, partial discharge, high temperature of oil, water and gas contamination, arcing also degrade the transformer oil. This degradation paves a conductive path for the current, and consequently, the insulating properties of the oil start deteriorating.

This degradation, if left unattended, can turn out to be fatal for the transformer. For this reason, power utility companies carry out the tan delta or the dissipation factor of transformer oil on a regular note, as per standards.

Importance Of Dissipation Factor In Transformer Oil

As the insulator starts gaining conductive properties, the resistive component starts increasing. Due to this, the current leads voltage by an angle lesser than 90° . The figure below shows this.

The tangent of this angle, delta, is known as the dissipation factor and is mathematically represented as:

Where, Ir is the resistive component, and Ic is the capacitive component. As the resistive component increases, the insulating power of the oil decreases, which increases the threat to the transformer.

To some extent, the value of Tan𝝳 is acceptable. However, beyond a threshold point, necessary actions need to be taken. To normalise the values, companies around the world use two main standards for the tan delta test, namely ASTM D924 and IEC 60247 for insulating liquids. The permissible dissipation factor is 0.1 (max) as per the IEC 60247 Standards.

Motwane’s MOTR Plus testing kit is fully automated and designed for accurate dissipation factor measurement. It would help companies carry out testing with ease. The testing kit also supports online data tracking that makes it easy to keep a record of the past values and helps to form a pattern.